6.81 Grades 760, 761

Elgin grades 760 and 761 are self-winding movements, 6/0 size.

Grade 760 has 30 working jewels, 761 has 27 working jewels.

Both grades have 360 degree rotors that wind in either direction.

Both grades have DuraBalance and DuraPower mainsprings.

Grade 760 has a "beat-adjusting" device that will enable

the watchmaker to place the watch in beat easier. This is

covered in detail under primary number 22.0.

The 6/0 self-winding movement is unique in design.

The following features should be noted:

- Power train and self-wind are located under the train and barrel

bridges.

- Approximately 30 less parts are in the movement, as compared to

other types of self-winders.

- The fewer number of parts make the movement very easy to service.

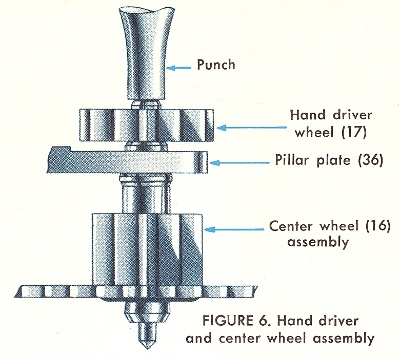

- The center wheel is located off center but is still the second

wheel in power sequence.

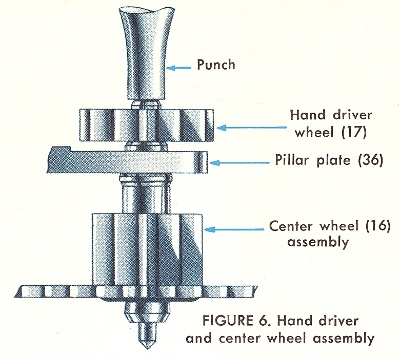

- A split hand driver gear drives the dial train.

- Cannon Pinion is not dimpled but is free on the hollow center post.

- When setting watch, split hand driver gear slips on lower center

wheel pivot.

- Winding and setting mechanism design adds to the thinness of

the movement.

- Movement is ready for servicing by removing one screw and lifting

off rotor.

- Long rotor post adds to the stability of the rotor.

- Rotor is cleaned as a unit and is not disassembled.

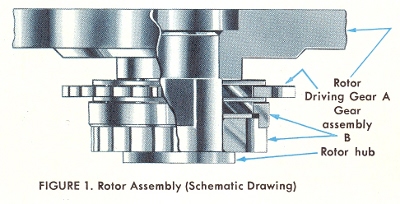

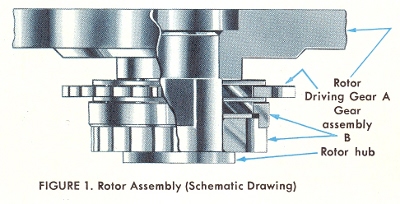

- Rotor consists of two directional driving gears. Each contains

three functional jewels. These gears are mounted on a hub that is

permanently attached to the rotor.

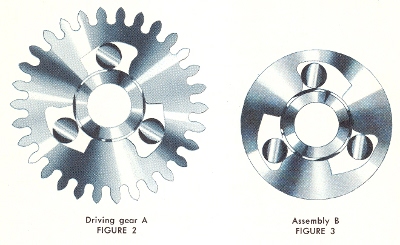

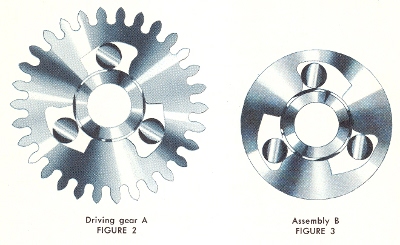

Driving gear A and gear assembly B (Figures 2 and 3) contain three

thin, round jewels. These jewels move freely in tapered elongated

slots. The slots in gear A are opposite in direction to those of

gear assembly B. As the rotor moves in a counter-clockwise direction,

the jewels in gear A bind between the side wall of the gear slot

and the hub. This action winds the mainspring through the selfwinding

train. Gear assembly B will idle. When the rotor reverses direction,

gear assembly B will wind and gear A will idle.

The self-winding train has two different winding ratios. When the

mainspring is nearly unwound, the rotor winds quickly in both

directions. With the mainspring nearly full-wound, the rotor turns

freely in only one direction, and mayor may not turn under its own

weight in the other direction. This action should not be

misinterpreted as a faulty condition if noted during servicing.

The rotor assembly is a single unit. It does not require disassembly

during service. Because of the necessity for special tools and

techniques, it is recommended that the watchmaker not attempt to

service the rotor assembly. If a replacement part is ever needed

for the rotor because of wear, the entire unit should be sent to

your nearest Authorized Elgin Material Distributor for exchange.

Your distributor will exchange the worn rotor with a refurbished

rotor at a nominal cost. Or, if you want a completely new rotor,

your distributor will supply it to you at a slightly higher cost.

Separate parts for the rotor are not available.

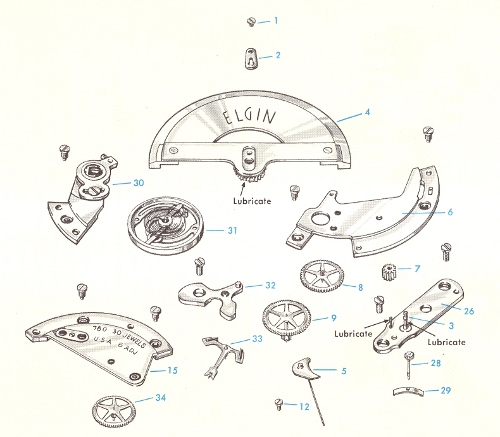

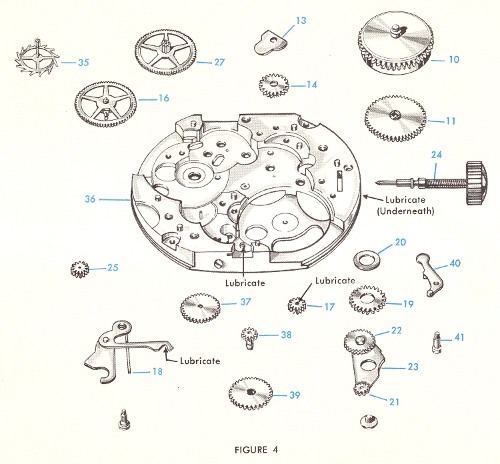

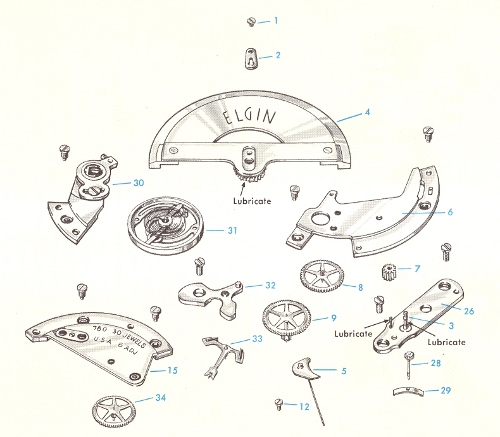

Exploded View of Movement

(1) Rotor retainer clomp screw

(2) Rotor retainer clamp

(3) Flanged rotor stud

(4) Rotor assembly

(5) Click

(6) Barrel bridge

(7) Rotor idler pinion

(8) First automatic winding wheel

(9) Second automatic winding wheel

(10) Barrel

(11) Ratchet wheel

(12) Idler ratchet wheel clamp screw

(13) Idler wheel ratchet clamp

(14) Ratchet idler wheel

(15) Train bridge

(16) Center wheel

(17) Hand driver wheel

(18) Minute wheel clamp and setting lever spring

(19) Winding and setting wheel

(20) Washer

(21) Winding wheel

(22) Setting wheel

(23) Rocker plate

(24) Stem

(25) Bevel pinion

(26) Center bridge

(27) Third wheel

(28) Sweep second pinion

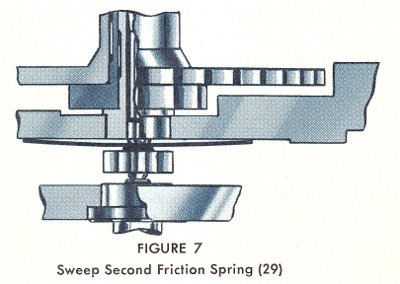

(29) Sweep second Friction spring

(30) Balance cock

(31) DuraBalance

(32) Pallet bridge

(33) Pallet

(34) Fourth wheel

(35) Escape wheel

(36) Pillar plate

(37) Minute wheel

(38) Cannon pinion

(39) Hour wheel

(40) Setting lever

(41) Setting lever screw

|

|

6.81 To Disassemble for Servicing

a) Remove hands, dial, hour wheel and cannon pinion from movement.

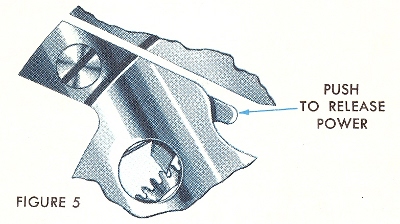

b) Remove rotor retainer clamp screw (1) and rotor retainer

clamp (2). When screw is removed, push clamp away from flanged

rotor stud (3) and remove with tweezers.

c) Remove rotor assembly (4) with tweezers or invert movement

and allow rotor to fall free.

NOTE: To clean rotor assembly see paragraph 6.92.

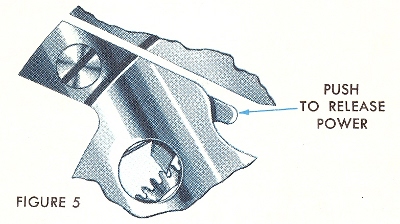

d) Let down mainspring slowly in normal manner. Note:

It is impossible to let down mainspring with rotor attached.

m) Remove minute wheel clamp and setting lever spring

assembly (18), also minute wheel.

n) Remove rocker plate assembly, winding and setting wheel (19)

and washer (20).

NOTE: Winding wheel (21) and setting wheel (22) are permanently

attached to rocker plate (23).

To lubricate see paragraph 6.91.

o) Remove stem (24) and bevel pinion (25).

p) Remove center bridge (26) and third wheel (27).

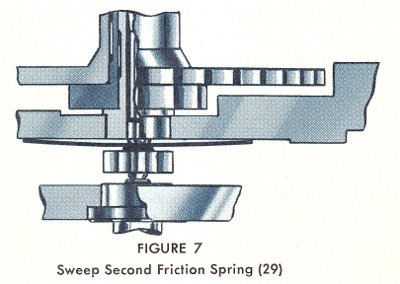

q) Remove sweep second pinion (28) (see figure 7).

1) Remove sweep second friction spring (29).

Caution should be exercised in removing the sweep

second friction spring. This spring is located between the

sweep second pinion and the pillar plate.

2) When reassembling movement the center bridge should be

in contact with the top of the sweep second pinion. In

this position the sweep second friction spring will be

under a slight tension.

6.82 To Reassemble, reverse the disassembly procedure.

6.9 To Service Elgin Grades 760 and 761.

This movement being disassembled according to procedures in

paragraph 6.8, care should be exercised to lubricate only

certain parts and to check certain points as given in paragraphs

6.91 and 6.92 before reassembling.

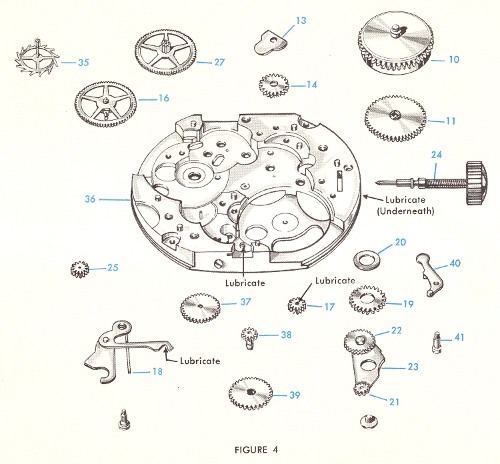

6.91 To Lubricate (see figure 4 for points of lubrication)

Proceed in the conventional manner, except that these points

should be carefully observed:

a) Do not disassemble the barrel. The mainspring is permanently

lubricated. To service, merely brush the barrel teeth and

re-oil the barrel arbor pivots with Elgin M-56B.

b) Lubricate with Elgin M-56B:

1) Rotor idler pinion post.

2) Flanged rotor stud.

3) Hand driver.

c) Lubricate with heavy oil or light grease such as Vaseline:

1) Rocker plate post.

2) Tip of set lever spring.

3) Ratchet idler wheel post.

d) Do not lubricate:

1) Winding wheel (in rocker plate).

2) Setting wheel (in rocker plate).

3) Barrel arbor.

4) Mainspring.

6.92 Clean rotor assembly in conventional manner without

disassembly. Rotor should be thoroughly dried after cleaning.

6.93 Check Points

When servicing, check the following points:

a) Spring tension on click (5) should not exert excessive

pressure on first automatic winding wheel.

b) Rotor gears should move freely in opposing directions.

c) Case screws should be tight to avoid their working loose

to interfere with rotor rotation.

|

The

The