Know Your Product

Know Your Product |

|

|

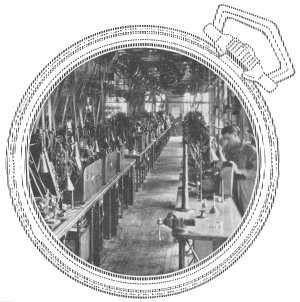

Part 6, The Screw Department, The Watch Word, May 1936Merton E. DoxeyEditor's Note - This is the sixth of a series of articles on the manufacture of a watch as conducted in the factory of The Elgin National Watch Company. It is our hope to acquaint our readers with the work of departments other than their own. |

|

||

|

In the Screw department might be appropriately called the largest manufacturing department in the factory, for a greater variety and larger number of finished materials are produced there than in any other room. In this department are made not only all the screws that are used in the factory (and there are hundreds of different kinds and sizes cataloged) but also makes the winding and setting mechanism for the watch, consisting of main wind wheel, ratchet wheel, click, bevel pinion, winding and setting clutch, setting lever, clutch levers and winding arbors. These parts are punched in the Spring department and delivered in blank form to the Screw department-with the exception of the clutch, bevel pinions and winding arbors which are made on automatic screw machines. These blanks are counterbored for screw heads. The flat wheels are then taken to the toothcutting job and teeth are hobbed. The wheels are heat treated at this stage and then ground to size, the top side glossed and ornamented. After a thorough cleaning they are ready for inspection. |

|

|||

|

The main wind wheels are fitted with a washer, the staffs of which are .001 of an inch longer than the thickness of the wheels so that when they are screwed in place they have enough freedom to turn easily. The setting and clutch levers are milled on special fixtures, the milling cutters being made to produce the required shape. The winding arbor is blanked and the pivot turned on staff-turning lathes in the Train department, and then delivered to this department where they are squared, grooved and threaded for the crown. These are then nickled to prevent rusting and then service crowns are screwed on so they can be used to wind the movements before they are finally cased. These service crowns are knurled, formed to shape, drilled and tapped on automatic machines. All the screws that are used in the watch are made on automatic machines designed and built within the factory. Drill rod is used in making the steel screws and it is purchased in sizes the exact diameter of the desired screw head. These rods are four feet in length and one rod will make approximately 1,200 small screws. The steel screws are taken from the automatic job, heat treated, loaded into blocks and the heads ground to the required length and the tops glossed. The brass and gold balance and timing screws are made on machines of a special design with an attachment for finishing the head of the screws. These finishing tools are of either sapphire or diamond and can be adjusted to produce screws accurate in weight to one onehundredth of a milligram. Automatic machines form and drill the safety roller blanks and hairspring studs for the Escape department and the cannon pinion blanks for the Train department. The regulators are received in blank form from the Spring department and the large, tapered hole bored so that it will hold to the dome. The two small holes on the pin arm are then drilled and broached on an automatic machine. The regulators are then tempered and the under side ground. At this point, the small, tapered brass pins are pushed into holes in the pin arm and cut to proper length, this operation being done on a press. The regulator is now drawn for the second time to soften the pins so they will bend when placed in position over the hairspring. They are then cemented on special blocks of steel and the top side ground and glossed. The regulator adjusting nuts and screws are also made in this department as well as various sizes of winding bars, and springs for case manufacturers. Automatic machines produce the small tapered pins used in the regulator as well as all hairspring pins used in the Escape department. |

||||

|

||||

|

|

||||

|

|

|||

|

|

||||

Comments to jsexton@elgintime.com